Procedure to Get GMP Certification in Malaysia:

Procedure to Get GMP Certification in Malaysia, Vertex Certifiers is a trusted GMP certification and consulting partner in Malaysia, providing end-to-end support to pharmaceutical, food, cosmetic, and medical manufacturing organizations. With strong expertise in WHO GMP, PIC/S GMP, NPRA GMP, and MOH-aligned GMP requirements, Vertex helps companies in Malaysia implement compliant systems that meet both local regulatory expectations and international export standards. We deliver gap assessment, GMP documentation, facility compliance support, staff training, internal audits, and regulatory inspection readiness, ensuring a smooth and time-bound certification process. Vertex Certifiers actively supports organizations across key Malaysian industrial hubs including Kuala Lumpur, Selangor, Shah Alam, Petaling Jaya, Johor Bahru, Penang, Melaka, Negeri Sembilan, Perak, and Kedah, helping manufacturers achieve GMP certification with confidence and sustained compliance.

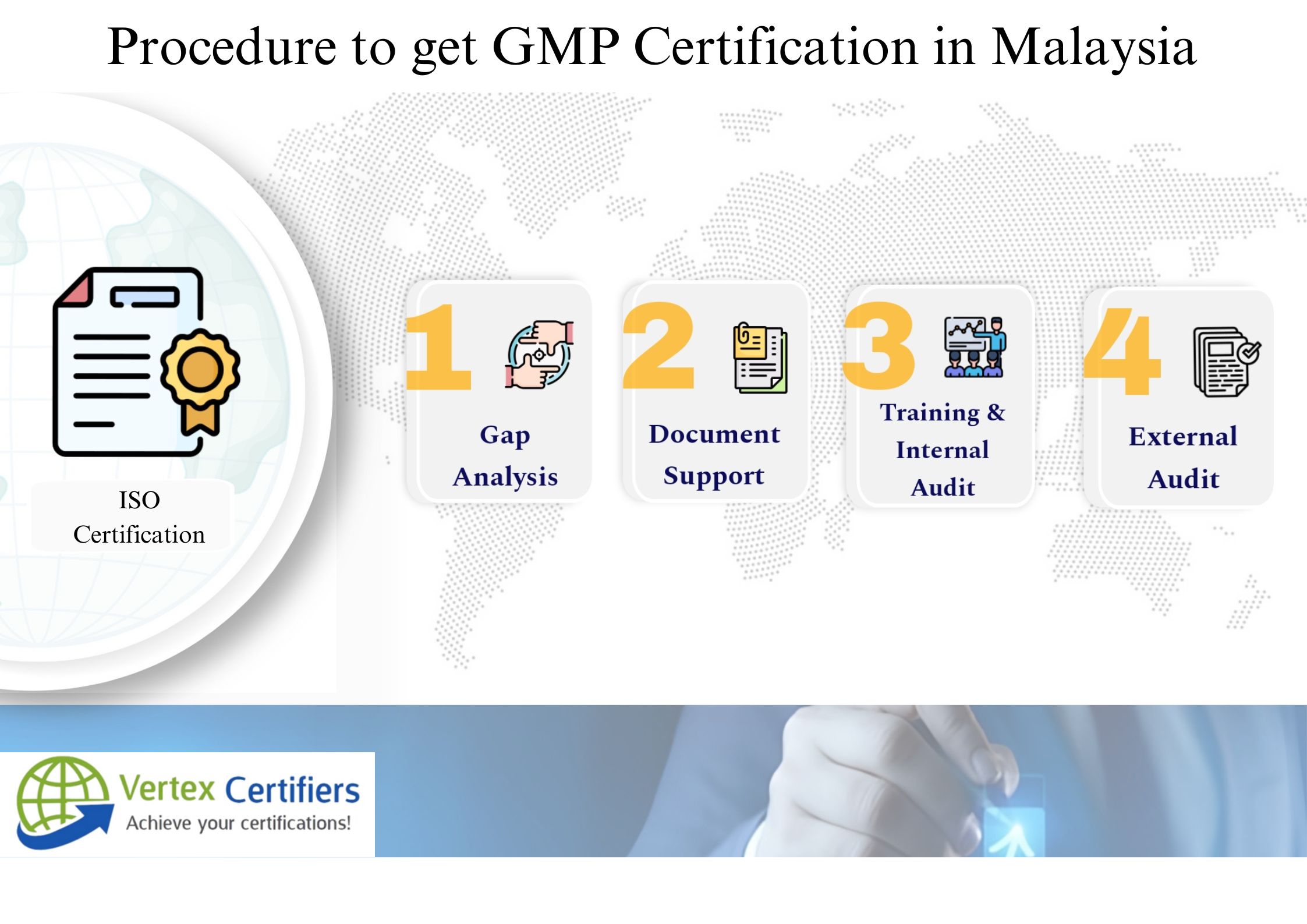

GMP certification in Malaysia follows a structured, step-by-step procedure that starts from identifying the right GMP standard and authority and ends with regulatory inspection, closure of findings, and ongoing surveillance over a 2–3 year validity cycle. Following a clear roadmap helps Malaysian manufacturers in pharmaceuticals, food, cosmetics, and medical devices achieve compliance, protect consumers, and unlock export markets

Introduction to GMP Certification

Good Manufacturing Practice (GMP) certification in Malaysia is a formal recognition that a manufacturing facility consistently produces safe, high-quality products in line with national and international regulatory expectations. It is critical for sectors such as pharmaceuticals, health supplements, traditional medicines, cosmetics, food and beverages, and medical devices, where poor controls can directly affect patient or consumer safety

Step by Step Procedure to Get GMP Certification in Malaysia

Procedure to Get GMP Certification in Malaysia

Achieving Good Manufacturing Practice (GMP) certification in Malaysia requires a structured, step-by-step approach covering systems, facilities, people, and documentation. While GMP principles remain consistent across industries, successful certification depends on correctly aligning your operations with the applicable GMP framework and implementing it effectively.

Step 1: Identify Applicable GMP Framework

The first step is to clearly define which GMP framework applies to your products and manufacturing activities. GMP expectations vary depending on whether you manufacture pharmaceuticals, food products, cosmetics, supplements, or medical devices, even though the core principles of quality, hygiene, and control remain similar.

Clarifying the applicable GMP scope at the beginning helps determine documentation depth, facility requirements, validation expectations, and inspection readiness, forming the foundation for the entire certification journey.

Step 2: Conduct GMP Gap Assessment

Once the GMP framework is defined, a comprehensive gap assessment is carried out to compare current practices against GMP requirements. This assessment evaluates how closely existing systems align with expected standards and identifies areas requiring improvement.

- Facility layout, zoning, and material/personnel flow

- Equipment qualification and operational suitability

- Personnel hygiene practices and GMP awareness

- Documentation control and data integrity

- Critical utilities such as HVAC, water, and compressed air

The output is a structured gap analysis report with a prioritized action plan to achieve full GMP readiness.

Step 3: Establish a GMP-Compliant Quality Management System (QMS)

GMP certification requires a well-defined Quality Management System (QMS) that governs how quality is planned, implemented, monitored, and improved across the organization.

- GMP quality policy and measurable quality objectives

- Quality Manual and Site Master File

- Standard Operating Procedures (SOPs) for all GMP activities

- Change control, deviation management, and CAPA systems

A strong QMS ensures consistency in operations and makes inspections smoother and more predictable.

Step 4: Facility & Infrastructure Compliance

GMP compliance depends heavily on facility design, equipment condition, and infrastructure control. Manufacturing premises must be suitable for the intended products and capable of preventing contamination, mix-ups, and quality defects.

- Cleanroom classification and segregation where applicable

- HVAC qualification and environmental monitoring

- Equipment IQ, OQ, and PQ execution

- Pest control, waste handling, and effluent management

Documented evidence of qualification and validation activities is essential for GMP certification.

Step 5: Personnel Training & Competency

People are central to GMP compliance. Even the best systems fail without trained and competent personnel who consistently follow procedures.

- GMP induction training for all employees

- Role-based SOP training

- Regular refresher training on hygiene and data integrity

- Training records, matrices, and effectiveness checks

A structured training program reduces human error and strengthens daily GMP discipline.

Step 6: Documentation & Record Management

GMP systems are documentation-driven, and weak record control is a common cause of non-compliance. A controlled documentation system ensures traceability, accountability, and data integrity.

- Batch manufacturing and packaging records

- Equipment logs, calibration, and maintenance records

- Raw material and packaging traceability

- Complaint handling and recall procedures

Proper document control builds confidence in the reliability of recorded information.

Step 7: Internal Audit & Mock Inspection

Before formal inspection, internal audits and mock GMP inspections are conducted to verify readiness and identify weaknesses.

- Planned internal audits across departments

- Root cause analysis and CAPA implementation

- Mock inspections simulating real audit conditions

These activities significantly reduce the risk of major findings during actual inspections.

Step 8: Application & Inspection Readiness

Once systems and facilities are fully implemented, the site prepares for GMP inspection. This includes final document review, staff preparedness, and verification of implementation.

Inspectors typically evaluate facilities, documents, records, and personnel understanding of GMP during on-site assessments.

Step 9: Observation Closure & Certification

Any inspection observations must be addressed through structured corrective and preventive actions supported by documented evidence.

Successful closure leads to GMP certification with defined validity, subject to ongoing compliance and periodic reviews.

Validity, Surveillance & Continuous Compliance

GMP certification has a fixed validity and requires continuous compliance. Organizations must maintain systems, manage changes, and sustain training to retain GMP status.

Expected Timeline for GMP Certification

- Gap assessment & implementation: 1–3 months

- Inspection & approval: 1–2 months

Most organizations complete the process within 2–4 months, depending on readiness.

Common GMP Challenges

- Poor facility layout and segregation

- Weak documentation and data integrity

- Incomplete training records

- Delayed or ineffective CAPA implementation

Why Choose Vertex Certifiers for GMP in Malaysia

Vertex Certifiers provides end-to-end GMP consulting and certification support for manufacturers in Malaysia across pharmaceuticals, food, cosmetics, supplements, and medical devices.

- Practical GMP gap analysis and implementation

- Tailored SOPs, QMS, and documentation

- Training, internal audits, and mock inspections

- SME-friendly, scalable GMP solutions

Get GMP Certified in Malaysia with Confidence

Partner with Vertex Certifiers for expert GMP gap analysis, documentation, training, internal audits, and inspection-ready support tailored to your industry and scale.

Contact Vertex Certifiers TodayOur Services

- GMP Certification

- GLP Certification

- GDP Certification

- Halal Certificate

- Organic Certificate

- CE Marking Certification

- RoHS Certification

- FDA Certification

- CMMI Certification

- Cyber Security

- VAPT Testing

- Security Assessment

Call to Action – Make Your Malaysian Manufacturing Globally Trusted

Strengthen product quality, safety, and compliance with internationally aligned GMP implementation.

- Free GMP readiness discussion

- Confidential GMP gap assessment

- Clear, practical roadmap to GMP compliance with defined timelines and milestones

Contact Vertex Certifiers for GMP Certification in Malaysia

✉️ info@vertexcertifiers.com

Kuala Lumpur · Selangor · Penang · Johor Bahru · Nationwide Malaysia